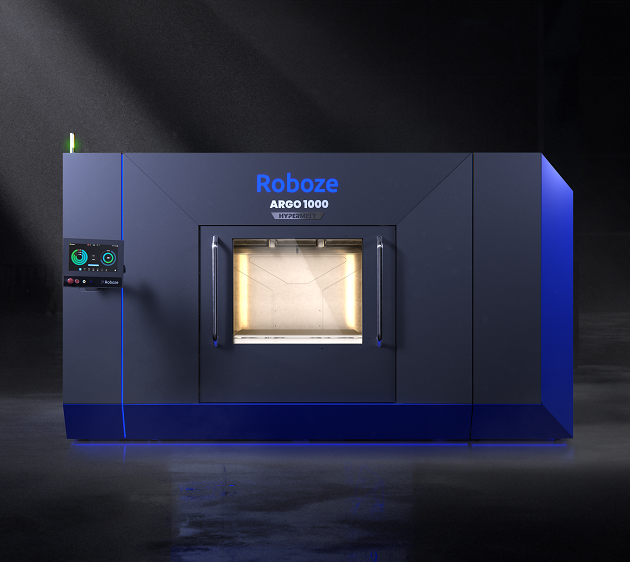

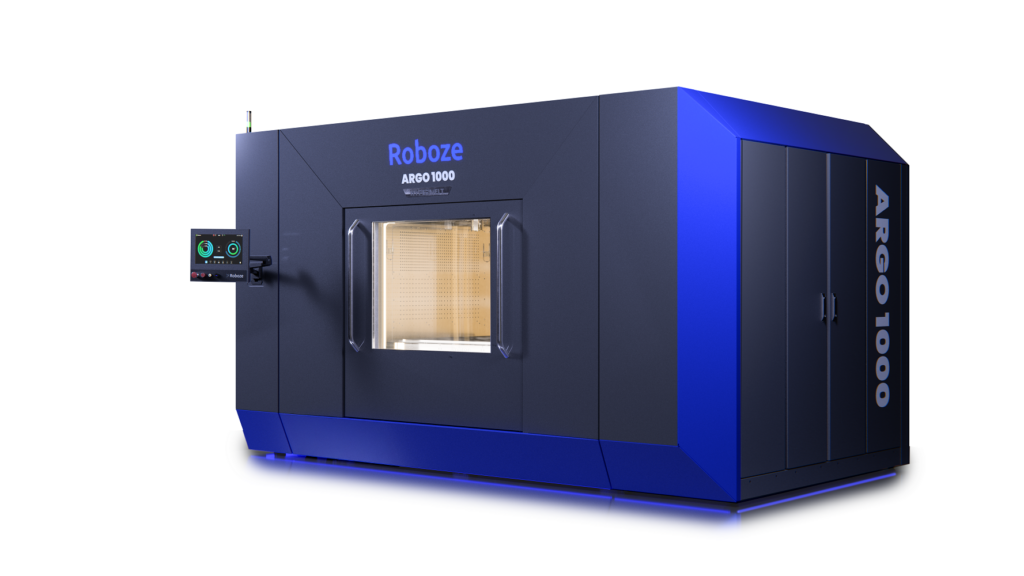

Biesterfeld installs Roboze’s Argo 1000 Hypermelt – the world’s largest pellet-based 3D printer

Biesterfeld, one of the leading international distributors of products and solutions in the world of specialty chemicals and the pharmaceutical and food industries, and Roboze, a leading company in the development and production of industrial 3D printing solutions, celebrate a big milestone in their successful, long-standing partnership by installing the first ever Argo 1000 Hypermelt 3D printer at Biesterfeld’s Lab and Innovation Center in Hamburg.

Setting new standards for large format 3D printing

Argo 1000 Hypermelt is the world’s largest pellet-based 3D printer, equipped with a best-in-class heated chamber up to 180°C, to quickly produce large format parts in incredibly strong super polymers and composites.

Thanks to its large work volume – 1000x1000x1000mm – nearly 40 by 40 by 40 inches – it is possible to print larger components and a greater number of parts all in a single job, allowing customers to satisfy different and changing needs while optimising time and reducing costs. The parts are being consolidated with a perfect thermal fusion of each layer in order to achieve exceptional mechanical properties, providing a strong impact on the mechanical properties of the final component.

The Argo 1000 Hypermelt allows to program parts production, analyse data and quickly predict and resolve downtime, thus increasing efficiency and mitigating the risks of printing failure. Furthermore, it prints parts with the best performing formulations to the maximum of their properties, allowing for fast and flexible metal replacement production.

Competitive edge for Biesterfeld and added value for customers

“As the first to have this printer, we are able to offer our customers groundbreaking new services”, says Dr. Johannes Martin, Market Manager Composites & Tooling at Biesterfeld. “The Argo 1000 Hypermelt will be used for training purposes and proof-of-principle projects. This means we utilise it for customer projects, allowing our clients to outsource these tasks to us. In doing so, we provide enhanced consulting and technical expertise.”

From advanced super polymers to high-performance composites, Biesterfeld can now execute a wide range of projects. Serving industries such as aerospace, motorsports, automotive, space, defence, oil & gas, robotics & industrial automation and mobility, the distributor will now also be able to leverage emerging technologies like Fused Granular Fabrication (FGF) to deliver even better solutions, particularly in the aerospace sector.

This unique position places Biesterfeld the distributor in an exclusive market position, providing the company with a significant competitive edge.

“The launch of Argo 1000 Hypermelt marks a new era of customised production,” said Levi Smith, Global Channel Development Director at Roboze. “We are very excited to take this important step with our valued partner Biesterfeld and look forward to the projects ahead.”

About Biesterfeld SE

Biesterfeld SE is the strategic holding company of the Biesterfeld Group, one of the international leading distribution and service companies in the field of plastics, rubber and specialty chemicals. Founded in 1906 in Hamburg, Germany, today the group has more than 1100 employees across more than 50 locations in Europe, North and South America, Asia and Africa and generates an annual revenue of 1.38 billion EUR (FY 2023). The fully family-owned company focuses on specialized market know-how and application-based technical advice across numerous industries in the business units Standard Polymers, Engineered Polymers, Performance Polymers, Rubbers, HealthCare, Industrial and Consumer.

About Roboze

Roboze is a leading company in the development and production of advanced solutions in the field of industrial 3D printing. Founded with the aim of transforming how companies design and produce components, Roboze offers comprehensive solutions for additive manufacturing with super polymers and composite materials, enabling applications in sectors such as aerospace, mobility, energy, and manufacturing. Roboze’s mission is to accelerate the adoption of 3D printing through continuous innovation and the provision of reliable and sustainable solutions.

Cover photo: The Argo 1000 Hypermelt 3D printer (Copyright Roboze, 2025)